LoVOC Fiberglass laminates

Lower emissions, better solution.

From lamination to application, Brianza Plastica helps you reduce VOC emissions at every stage.

LoVOC Elyplan Fiberglass laminates

Lower emissions for better solutions

Compliant with the most stringent parameters of the new European regulations on VOC reduction.

Lower emissions during processing for healthier working environments.

Reduced VOC emissions from the finished product, both into the environment and enclosed spaces.

reduction

LoVOC FIBERGLASS LAMINATES

With its new LoVOC laminates, Brianza Plastica provides a concrete, high-performance and cutting-edge solution that meets the growing demands for sustainability in manufacturing, as well as the latest European regulations on the reduction of Volatile Organic Compound (VOC) emissions. This range of laminates combines innovation, sustainability and a focus on health, anticipating the needs of a market increasingly aware of environmental impact and workplace quality.

Developed through years of dedicated research, the innovative resin used in LoVOC laminates reduces emissions throughout the product’s entire life-cycle. This results in healthier working environments and more sustainable production processes, enhancing every project with high performance and a strong commitment to health and environmental responsibility.

LoVOC is available in the following product ranges:

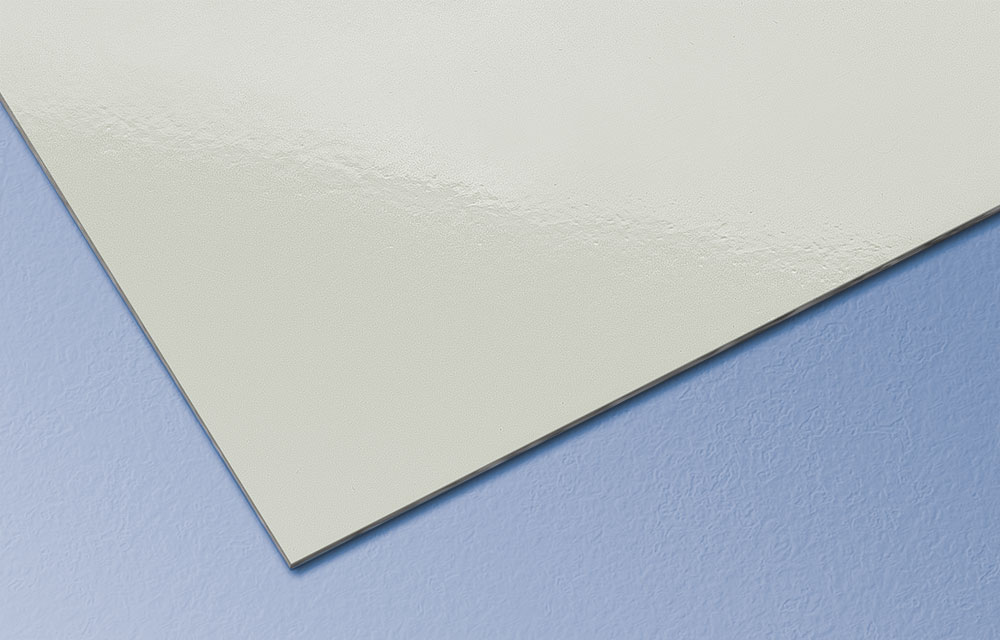

Elyplan Std

Elyplan Std is known for its excellent value for money, making it an effective solution at a competitive price.

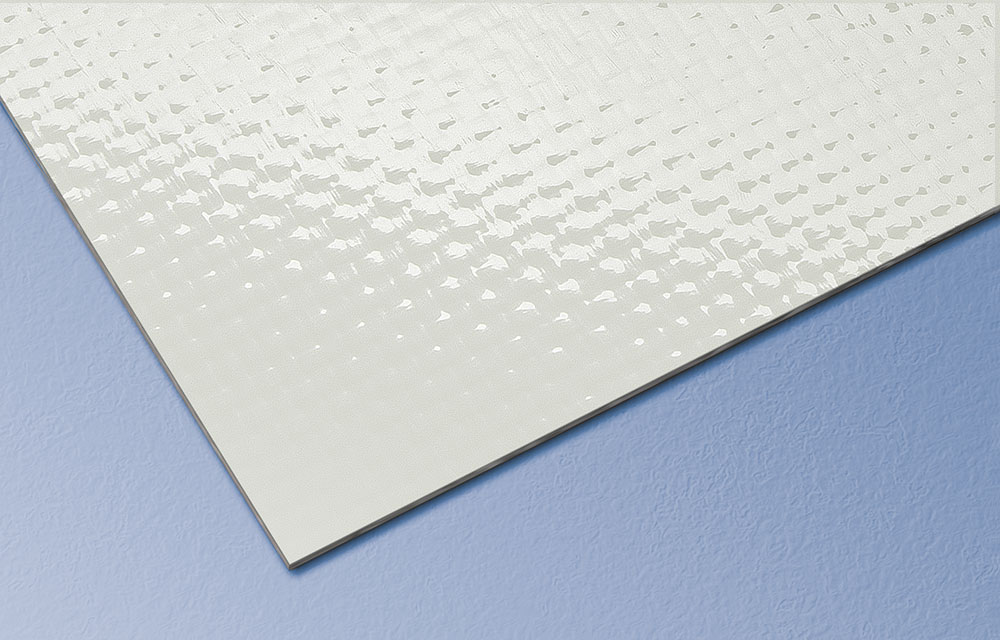

Elyplan Extra-glass

Elyplan Extra-Glass combines light weight with high mechanical strength in a single product.

Why choose Brianza Plastica GRP laminates with LoVOC technology?

Discover the advantages of Elyplan for healthier environments, sustainable production processes, and high-performance projects.

RESISTANCE

AND DURABILITY

Brianza Plastica’s laminates offer excellent resistance to corrosive agents, are completely waterproof, have low thermal expansion and ensure long-lasting performance.

HYGIENIC

SURFACES

Easy to clean and certified for food contact, they do not release substances harmful to food products.

EASY

TO REPAIR

In case of accidental damage, fiberglass laminates can be easily repaired, maintaining their functionality and aesthetics unchanged.

HIGH IMPACT

RESISTANCE

Robust and resistant to impact and stress, ideal for environments exposed to heavy use and continuous movement.

SUSTAINABILITY

FOR BONDING

Suitable for cladding surfaces to be renovated and for bonding to expanded polystyrene, extruded polystyrene and polyurethane substrates.

FOOD CONTACT

CERTIFICATION

EC-certified according to Regulation (EC) No. 1935/2004, for direct contact with food.

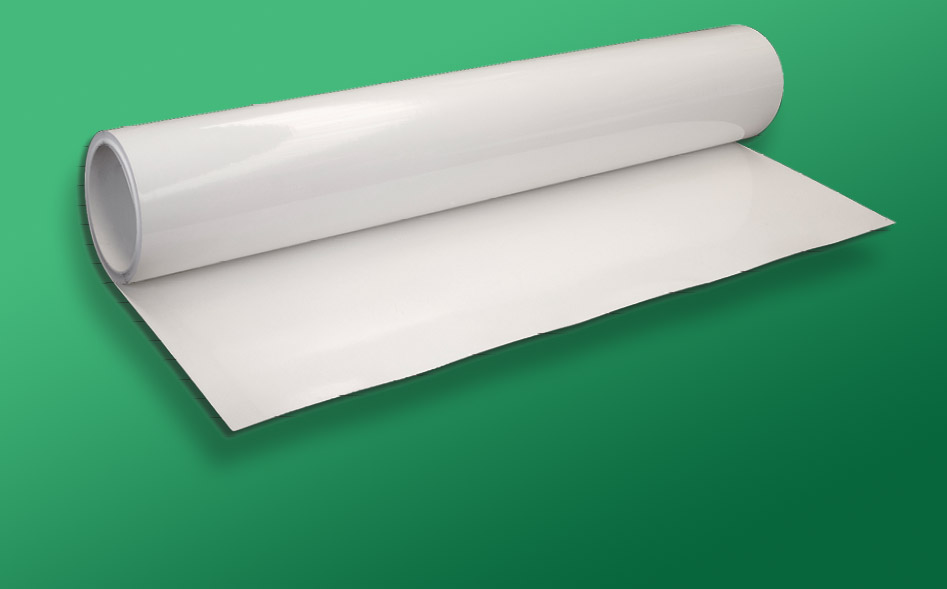

ELYPLAN laminates

continuous lamination

Ideal for application in temperature-controlled and recreational vehicles, cold rooms, and cleanrooms, it offers smooth, highly resistant, and easily washable surfaces. Continuous hot production ensures perfect flatness at competitive prices.

PRODUCT DIMENSIONS (ROLLS / SHEETS)

- Thickness: from 0.8 to 3 mm

- Width: up to 3,200 mm

- Length: on request

Brianza Plastica Group

The Brianza Plastica Group is made up of three companies that contribute to the study, production and supply of high-quality materials and products, thus making the Group a leader in the field of fiberglass laminates and industrial and civil insulation. All Brianza Plastica products are made in Italy in the company’s five production plants.

Fiberglass sheets and rolls are produced in four production facilities entirely dedicated to these products: Carate Brianza, Ostellato, and two in San Martino di Venezze.

The companies making up the Brianza Plastica Group are:

- Brianza Plastica S.p.A.

- Plasti-Bat S.a.s.

- Brianza USA Corporation